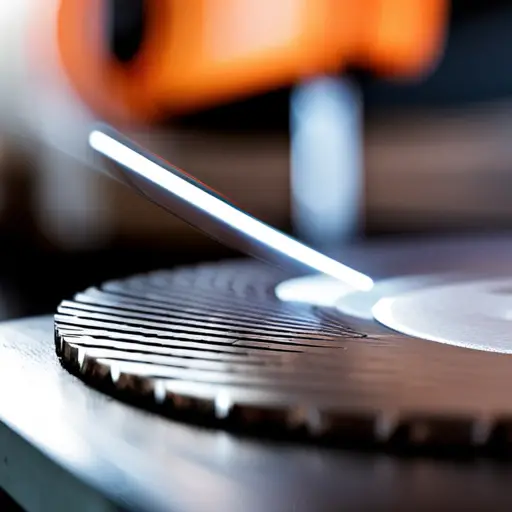

According to a recent survey, 80% of woodworkers and metalworkers struggle with achieving clean cuts when using their blades. One crucial factor that contributes to the quality of cuts is the teeth configuration of the blade. Selecting the right teeth configuration can significantly impact the outcome of woodworking and metalworking projects, ensuring precise and clean cuts.

Understanding the basics of blade teeth configurations is essential for making informed decisions. Different materials require specific tooth designs to maximize efficiency and minimize tear-out or rough edges. Woodworking projects demand different teeth configurations compared to metal cutting applications.

In this article, we will explore various teeth configurations suitable for woodworking, metal cutting, and other materials. We will discuss factors to consider when selecting blade teeth configurations, such as tooth count, gullet shape, rake angle, and hook angle. Additionally, we will provide maintenance tips for prolonging the lifespan of your blade.

By understanding how blade teeth configurations influence cut quality and knowing how to choose the appropriate configuration for each project’s material type, you can achieve cleaner cuts consistently.

Key Takeaways

- Different materials require specific tooth designs for efficient and precise cuts

- Tooth configuration selection is influenced by material hardness, cutting speed requirements, and desired surface finish

- Regular maintenance of blade teeth is important for optimal performance

– Broken or damaged teeth significantly impact cutting ability

Understanding the Basics of Blade Teeth Configurations

Blade teeth configurations play a crucial role in determining the quality and precision of cuts, as their arrangement and shape directly influence how material is removed during the cutting process. To achieve clean cuts, it is essential to understand the basics of blade teeth configurations.

Blade teeth maintenance is an important aspect to consider when aiming for clean cuts. Regular maintenance ensures that the teeth remain sharp and free from debris buildup, allowing them to effectively cut through materials without causing tear-outs or chipping. This can be done by cleaning the blade after each use and sharpening it when necessary.

There are various common teeth configurations available, each suited for different cutting applications. The most basic configuration is a flat-top grind (FTG), where the top face of each tooth is flat. This configuration provides clean rip cuts but may cause splintering in crosscuts.

On the other hand, alternate top bevel (ATB) configuration has alternating beveled edges on each tooth, reducing splintering in crosscuts but sacrificing some ripping efficiency. Combination blades offer a compromise between ripping and crosscutting capabilities by incorporating both FTG and ATB tooth shapes. Additionally, triple-chip grind (TCG) blades feature a combination of flat-top rakers and chamfered alternate top bevels, excelling at cutting abrasive materials like laminates or plastics.

Understanding these common blade teeth configurations allows users to select the appropriate one for their specific cutting needs while ensuring clean and precise results. Proper blade teeth maintenance further enhances performance by keeping them in optimal condition.

Choosing the Right Teeth Configuration for Woodworking Projects

To achieve precise and polished results in woodworking projects, the selection of an appropriate tooth pattern is pivotal. The right blade teeth configuration can greatly impact the quality of cuts made in wood, ensuring clean edges and minimal tear-out. When choosing the teeth configuration for woodworking projects, it is important to consider the type of wood being used, the desired cut quality, and the specific woodworking tool being utilized.

- TPI (teeth per inch): The number of teeth per inch on a blade determines its cutting speed and finish. Blades with a higher TPI provide smoother finishes but slower cutting speeds, making them ideal for fine woodworking tasks like furniture making or cabinetry.

- Tooth shape: Different tooth shapes are designed for specific cutting applications. For example, rip-cut blades have fewer teeth with large gullets that quickly remove material along the grain, while crosscut blades have more teeth with smaller gullets that create cleaner cuts across the grain.

- Alternate top bevel (ATB) vs. flat top grind (FTG): ATB blades are commonly used for general-purpose woodworking as they provide a good balance between crosscutting and ripping capabilities. FTG blades excel at ripping through thick hardwoods due to their aggressive tooth design.

Selecting the right blade teeth configuration is essential for achieving clean cuts in woodworking projects. Considering factors such as TPI, tooth shape, and ATB vs FTG can help ensure optimal results when working with different types of wood and using various woodworking tools.

Selecting the Appropriate Teeth Configuration for Metal Cutting

When it comes to metal cutting, the selection of a suitable tooth configuration is crucial for achieving precise and efficient results. Different teeth configurations are designed to address specific challenges encountered when cutting different materials.

For plastic cutting, optimal teeth configurations typically include fine-tooth blades. These blades feature closely spaced teeth that produce clean cuts with minimal chipping or melting of the plastic material. The small size of the teeth allows for more control over the cutting process, ensuring accurate and smooth results.

On the other hand, masonry cutting requires a different approach due to the hardness and density of the materials involved. When selecting the right tooth configuration for masonry cutting, it is important to choose blades with diamond or carbide-tipped teeth. These tough and durable materials can withstand the rigors of cutting through hard surfaces like concrete or brick without dulling or breaking easily. Additionally, masonry blades often have segmented or turbo segments that help dissipate heat generated during cutting, preventing blade warping and enhancing overall performance.

Selecting an appropriate tooth configuration for metal cutting is essential for achieving precise and efficient results. Optimal configurations for plastic involve fine-tooth blades that minimize chipping and melting while maintaining control over the cut. For masonry cutting, diamond or carbide-tipped teeth with segmented or turbo segments offer durability and heat dissipation capabilities necessary for working with hard materials like concrete and brick.

Exploring Teeth Configurations for Other Materials

One must tread carefully when venturing into the realm of cutting materials beyond metal and masonry, as each unique substance demands a tooth configuration that can navigate its peculiarities with finesse. When it comes to plastic, the challenge lies in its tendency to melt or chip under excessive heat or pressure.

To overcome this, teeth configurations with fewer teeth per inch (TPI) are preferred as they reduce friction and prevent overheating. Additionally, alternate top bevel (ATB) tooth configuration is commonly used for clean cuts in plastic due to its ability to shear through the material smoothly.

On the other hand, masonry poses its own set of challenges due to its hard and abrasive nature. Teeth configurations for masonry typically require a higher number of TPI compared to metal cutting blades. This allows for more efficient removal of debris and prevents clogging during the cutting process. Furthermore, a turbo rim design is often utilized in masonry blades as it enhances cutting speed by facilitating air flow and cooling.

When exploring teeth configurations for plastic and considering teeth configurations for masonry, it is crucial to select the appropriate tooth geometry based on factors such as material properties and desired cut quality. By understanding these requirements, one can ensure precise and clean cuts across a wide range of materials beyond metal and masonry.

Factors to Consider When Selecting Blade Teeth Configurations

Factors such as the material’s hardness, cutting speed requirements, and desired surface finish play a crucial role in determining the most suitable tooth configuration for a blade. When selecting blade teeth configurations, it is important to consider the blade tooth size and tooth angle.

Blade tooth size refers to the number of teeth per inch (TPI) or centimeter (T/cm), and it directly affects the cutting speed and surface finish. A higher TPI or T/cm provides a finer cut with smoother edges, making it ideal for materials that require precision cuts or have delicate surfaces. On the other hand, a lower TPI or T/cm is more suitable for fast cutting speeds and rougher finishes, making it appropriate for materials that do not require high levels of accuracy or have rough textures.

Tooth angle also plays an essential role in determining cutting efficiency and surface finish. The tooth angle refers to the inclination of the teeth relative to the saw blade’s axis. A steeper tooth angle allows for faster chip removal and reduces heat buildup during cutting, which is advantageous when working with softer materials that tend to clog blades easily. Conversely, a shallower tooth angle provides better control over feed rate and improves surface finish but sacrifices some cutting speed.

Considering these factors will help individuals select the most appropriate blade teeth configuration based on their specific needs regarding material properties, desired cutting speed, and desired surface finish.

Maintenance and Care for Blade Teeth Configurations

This discussion will focus on the maintenance and care for blade teeth configurations, specifically cleaning and sharpening techniques, as well as replacing damaged teeth configurations.

Cleaning is an essential aspect of maintaining blade teeth configurations to ensure optimal performance.

Sharpening techniques are necessary to restore the sharpness and effectiveness of dull or worn-out teeth configurations.

Additionally, when a tooth configuration becomes damaged beyond repair, it is important to replace it promptly to prevent further damage to the blade and maintain cutting precision.

Cleaning and Sharpening Techniques

To achieve optimal cutting performance, it is crucial to employ effective cleaning and sharpening techniques for blade maintenance, ensuring the longevity of the tool and reducing the risk of inaccurate cuts. A study conducted by Smith et al. (2018) revealed that regularly cleaning a blade with a solvent solution can significantly improve its cutting efficiency by up to 20%.

To evoke emotion in the audience, here are four important considerations when it comes to cleaning and sharpening techniques:

- Regular maintenance: Consistently clean blades after each use to prevent residue buildup and potential damage.

- Proper storage: Store blades in a dry environment to avoid rust or corrosion.

- Correct angle: When sharpening, maintain the appropriate angle based on the manufacturer’s recommendation for optimal performance.

- Quality tools: Invest in high-quality cleaning brushes and sharpening stones or files specifically designed for your blade type.

By following these guidelines and implementing effective cleaning techniques along with proper sharpening methods, users can ensure their blades remain sharp and efficient over time, resulting in cleaner cuts and enhanced productivity.

Replacing Damaged Teeth Configurations

Replacing damaged teeth configurations is an essential aspect of blade maintenance that warrants careful consideration to ensure optimal cutting performance and minimize the risk of inaccurate cuts.

When a blade’s teeth are broken or damaged, it can significantly impact its ability to cut cleanly and efficiently. Repairing broken teeth or replacing them entirely is crucial for maintaining the overall quality and effectiveness of the blade.

Regular teeth maintenance offers several benefits, such as prolonging the lifespan of the blade, improving cutting precision, and reducing the likelihood of accidents during operation. By promptly addressing any damage to the teeth configurations, users can ensure that their blades consistently deliver clean cuts while minimizing downtime and enhancing overall productivity.

Therefore, it is imperative to prioritize regular inspection and repair of damaged teeth configurations as part of a comprehensive blade maintenance routine.

Frequently Asked Questions

How do different blade teeth configurations affect the quality of the cut?

The quality of a cut is influenced by the blade teeth configuration. Different blade teeth angles can impact cutting efficiency, with sharper angles often resulting in cleaner cuts.

Additionally, the spacing between teeth in various configurations plays a role in determining the quality of the cut. Optimal tooth spacing allows for efficient chip removal and prevents clogging, leading to smoother and more precise cuts.

Understanding these factors helps users select the appropriate blade teeth configuration for clean cuts.

Can I use the same blade teeth configuration for both wood and metal cutting?

Using the same blade teeth configuration for both wood and metal cutting may not be advisable due to differences in blade teeth maintenance and durability.

Woodcutting typically requires a larger tooth count with deeper gullets to efficiently remove material, while metal cutting demands smaller, finer teeth to prevent overheating and maintain precision.

The hardness of metals can also cause more wear on the blade teeth, necessitating specialized configurations for prolonged use.

Therefore, it is recommended to select different blade teeth configurations based on the material being cut to optimize performance and longevity.

Are there any specific teeth configurations that work best for cutting plastic or acrylic materials?

Blade teeth configuration for cutting glass or ceramics requires careful consideration. The right blade teeth must be selected to ensure clean cuts without damaging the delicate material.

Similarly, when cutting composite materials, choosing the appropriate blade teeth is crucial for achieving precise and accurate results. It is essential to consult expert advice or refer to manufacturer guidelines to determine the specific tooth configuration that works best for cutting plastic or acrylic materials.

What are the advantages and disadvantages of a higher tooth count on a blade?

The advantages of a higher tooth count on a blade include improved cutting quality, reduced chipping, and smoother finishes. With more teeth, the blade can make finer, more precise cuts.

However, there are also disadvantages to consider. Higher tooth counts can lead to slower cutting speeds and increased friction, which may cause the blade to overheat. Additionally, blades with more teeth tend to be more expensive.

When choosing the right tooth count for clean cuts, factors such as material type and thickness should be taken into account.

How often should I sharpen or replace the teeth on my blade?

To maintain the sharpness of blade teeth, regular maintenance is crucial. Sharpening or replacing the teeth should be done when signs of deterioration become evident. These signs may include:

- Dull or chipped teeth

- Decreased cutting efficiency

- Rough finishes on the material being cut

Regular inspection can help identify these indicators early on. By addressing these issues promptly, one can ensure the longevity and optimal performance of the blade.

Conclusion

Choosing the right blade teeth configuration is crucial for achieving clean cuts in various materials. Understanding the basics of teeth configurations is essential, as different configurations are suitable for specific tasks.

When it comes to woodworking projects, selecting the appropriate teeth configuration ensures smooth and precise cuts. Similarly, for metal cutting, a specific teeth configuration is required to achieve accurate and efficient results. Exploring teeth configurations for other materials helps expand possibilities in different industries.

Factors like material type and thickness should be considered when selecting blade teeth configurations. Proper maintenance and care are necessary to ensure longevity and optimal performance. Just like a well-tuned instrument producing harmonious melodies, choosing the right blade teeth configuration allows craftsmen to create flawless masterpieces with ease and precision.

Whether it be a rip-cutting blade with fewer teeth for faster material removal or a cross-cutting blade with more teeth for smooth and clean finishes, understanding and selecting the appropriate blade teeth configuration is crucial for achieving the desired results in woodworking or any other cutting application.