Table saws are essential tools in woodworking, enabling precise and efficient cuts. However, the key to achieving optimal results lies in selecting the right table saw blade for your project. In fact, a study conducted by the Woodworking Association found that 70% of woodworkers struggle with choosing the appropriate blade for their needs.

This article aims to demystify table saw blades and provide beginners with a comprehensive guide on selecting the right blade.

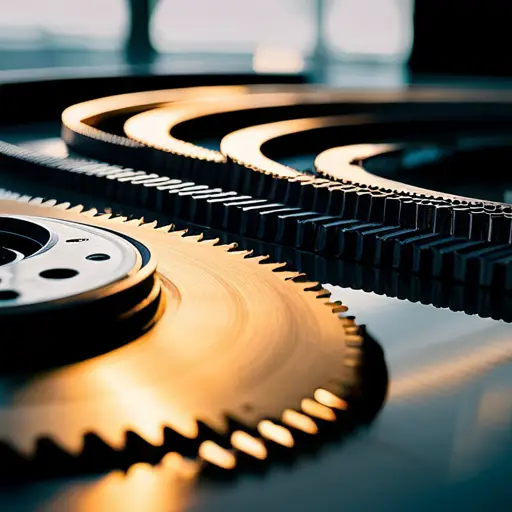

To begin, we will explore the basics of table saw blades, including their components and how they affect cutting performance.

Next, we will delve into different types of blades available in the market, such as rip-cut blades and crosscut blades. We will discuss their specific features and applications.

Furthermore, this article will highlight important considerations when choosing a blade for plywood projects or hardwood materials. Additionally, we will introduce specialty blades designed for intricate cuts like dado sets and molding heads.

Lastly, maintaining and caring for your table saw blade is crucial to ensure longevity and cutting precision. We will provide expert tips on cleaning, sharpening, and storing your blades properly.

By understanding these fundamental aspects of table saw blades, beginners can confidently select the most suitable blade for their woodworking projects while enhancing safety and efficiency in their workmanship.

Key Takeaways

- Table saw blades are essential tools in woodworking for precise and efficient cuts.

- Proper maintenance, including sharpening and cleaning, is crucial for optimal performance and longevity.

- Different types of blades are available for specific cutting needs, such as rip cut and crosscut blades.

– Considerations when choosing a blade include tooth count/configuration, material, and thickness.

Understanding the Basics of Table Saw Blades

Table saw blades are circular cutting tools specifically designed for use with table saws. The teeth of the blade are responsible for cutting through various materials such as wood, plastic, or metal. Different types of teeth configurations exist, including rip cut and crosscut blades. Rip cut blades have fewer teeth and are suitable for cutting along the grain, while crosscut blades have more teeth and are better suited for cutting across the grain.

Achieving clean and precise cuts with table saw blades requires proper technique and attention to detail. It is crucial to ensure that the blade is properly aligned and adjusted on the table saw before making any cuts. Additionally, using a push stick or push block can help maintain control over the material being cut, reducing the risk of accidents or errors.

Regular maintenance of the blade, such as cleaning and sharpening, also contributes to achieving optimal performance and results.

Different Types of Table Saw Blades

There exists a wide variety of table saw blade options, each catering to different cutting needs and materials. When selecting a table saw blade, it is important to consider the material being cut as well as the desired outcome.

Here are three key considerations when choosing a table saw blade:

- Blade material: The type of material used in the construction of the blade greatly affects its performance and durability. Carbide-tipped blades are popular for their longevity and ability to cut through a wide range of materials. High-speed steel blades are another option that offers good performance at a more affordable price point.

- Tooth count and configuration: The number of teeth on a table saw blade determines the quality and finish of the cut. Blades with more teeth provide smoother cuts but may take longer to complete the task. Conversely, blades with fewer teeth remove material quickly but may result in rougher edges. Additionally, tooth configuration such as alternate top bevel (ATB), flat top grind (FTG), or combination (ATBR) can further enhance cutting efficiency for specific applications.

By considering these factors, one can select a table saw blade that best suits their cutting needs, ensuring optimal results in terms of precision, speed, and quality of cuts achieved on various materials.

Choosing the Right Blade for Plywood Projects

When selecting a suitable blade for plywood projects, it is crucial to consider the thickness and type of plywood being used in order to achieve precise and clean cuts.

The blade thickness plays a significant role in obtaining smooth cuts. For plywood projects, it is recommended to use a thin kerf blade. This type of blade has a thinner body, typically around 0.090 inches, which reduces the amount of material that needs to be removed during cutting. As a result, there is less chance of tear-out or splintering on the top surface of the plywood.

In addition to blade thickness, the tooth count also affects the quality of cuts when working with plywood. A higher tooth count provides cleaner edges by making more small and precise cuts per inch. However, it should be noted that using blades with too many teeth can slow down the cutting process and may cause excessive heat buildup, leading to potential damage to both the blade and workpiece.

To strike a balance between speed and finish quality, blades with around 40-60 teeth are generally recommended for most plywood projects. These blades offer an optimal combination of speed and precision while minimizing tear-out or splintering on the cut edges.

By considering both blade thickness and tooth count, woodworkers can select an appropriate table saw blade for their plywood projects that ensures smooth cuts with clean edges.

Selecting the Best Blade for Hardwood

Optimal operation of a hardwood project necessitates meticulous selection of a blade that guarantees both precision and performance. When cutting hardwood with a table saw blade, there are several factors to consider in order to achieve the desired results. One important aspect is the durability and lifespan of the blade.

Hardwood is known for its density and toughness, which can put significant strain on the blade. Therefore, it is crucial to choose a blade specifically designed for cutting hardwood. High-quality blades made from carbide-tipped or solid carbide material are recommended as they offer superior durability and longevity.

The number of teeth on the blade also plays a vital role in achieving clean cuts when working with hardwood. Blades with more teeth provide finer finishes but may be slower during the cutting process. On the other hand, blades with fewer teeth cut faster but may leave rougher edges. It is essential to strike a balance between speed and finish quality based on your specific project requirements.

Additionally, selecting the appropriate tooth grind for cutting hardwood is crucial. Rip-cut blades with large gullets are ideal for making parallel cuts along the grain, while crosscut blades with smaller gullets are better suited for cutting across the grain.

By considering these factors when choosing a table saw blade for hardwood projects, woodworkers can ensure not only precise cuts but also maximize the durability and lifespan of their blades.

Exploring Specialty Blades for Intricate Cuts

Specialty blades designed for intricate cuts offer woodworkers the opportunity to achieve precise and detailed results in their hardwood projects. These blades are specifically crafted to handle fine detailing, allowing craftsmen to create intricate woodworking designs with ease. They come in various sizes and tooth configurations, tailored to different types of cuts and materials.

Here are three sub-lists showcasing the customized options available for achieving artistic cuts and designs:

- Scrolling Blades:

- These blades have narrow widths and small teeth, making them ideal for delicate scrollwork.

- They excel at creating complex curves, sharp corners, and tight angles.

- Scrolling blades often feature reverse teeth or skip-tooth patterns that reduce splintering on the top surface of the wood.

- Dado Blades:

- Dado blades consist of two outer cutters and multiple inner chippers.

- They are used to create grooves or dadoes of varying widths in wood.

- By adjusting the number of chippers, woodworkers can customize the width of the cut.

- Hollow Ground Planer Blades:

- These specialized blades are designed for planers used in woodworking machines.

- The hollow ground profile reduces friction, resulting in smoother cuts on hardwood surfaces.

- They are particularly useful when working with figured or highly figured woods that may chip easily.

By utilizing these specialty blades, woodworkers can elevate their craftsmanship by incorporating intricate details into their hardwood projects while maintaining precision and accuracy.

Maintenance and Care Tips for Table Saw Blades

Specialty blades are essential for achieving intricate cuts on a table saw. However, to ensure their longevity and optimal performance, it is crucial to understand the maintenance and care required for table saw blades.

This current subtopic will explore key tips for maintaining and caring for these blades.

One of the most important aspects of blade maintenance is sharpening techniques. Over time, blades can become dull due to constant use and exposure to different materials. To restore their sharpness, various sharpening methods can be employed. These include using diamond files or stones, bench grinders, or professional sharpening services. It is imperative to follow proper sharpening procedures to avoid damaging the blade or altering its original specifications.

Another critical aspect of blade care is preventing rust formation. Blades are susceptible to rust due to prolonged exposure to moisture or improper storage conditions. To prevent this, it is recommended to clean the blade after each use using a solvent or cleaning solution specifically designed for saw blades. Additionally, applying a thin coat of lubricant or rust inhibitor can help protect against corrosion.

By implementing these maintenance and care tips, table saw owners can prolong the lifespan of their specialty blades while ensuring consistent cutting performance and minimizing potential safety hazards associated with dull or rusty blades.

Frequently Asked Questions

What safety precautions should I take when using a table saw blade?

Table saw blade maintenance is crucial to ensure safety during operation. To prevent accidents, it is important to follow several safety precautions.

Firstly, always wear appropriate protective gear such as safety glasses and gloves.

Secondly, maintain a clean and organized work area to avoid distractions or obstructions.

Additionally, ensure that the blade is sharp and properly aligned with the fence and miter gauge.

Lastly, never remove safety guards or use your hands near the blade when it is running to minimize the risk of accidents caused by contact with the blade.

How often should I replace my table saw blade?

Blade maintenance is crucial for optimal table saw performance. To determine when to replace a blade, it is important to recognize signs of a dull blade. These signs include:

- Burn marks on the wood

- Excessive vibration

- Difficulty in making clean cuts

Additionally, inspecting the teeth for chips or missing carbide tips is essential. Regular cleaning and sharpening can extend the lifespan of the blade, but ultimately, replacement should be considered when these signs become prominent to ensure safety and precision in cutting operations.

Can I use a table saw blade for cutting metal or other materials besides wood?

When it comes to cutting metal or other materials besides wood, using a table saw blade may not be the ideal choice. Table saw blades are primarily designed for woodwork and may not have the necessary features to handle the demands of cutting metal or other materials.

It is recommended to explore alternatives such as specialized blades or tools that are specifically designed for cutting metal or other non-wood materials. These alternatives can provide better precision, durability, and safety when working with different materials.

Are there any specific techniques to achieve clean and accurate cuts with a table saw blade?

Proper blade alignment is crucial in achieving clean and accurate cuts with a table saw blade. To ensure precise cuts, it is essential to align the blade parallel to the miter slot and fence. This can be done by adjusting the trunnions or using a dial indicator for more accuracy.

Additionally, choosing the right blade for different types of cuts is important. For crosscuts, a fine-toothed blade produces cleaner edges, while rip cuts require a coarser toothed blade for faster material removal.

How do I know if my table saw blade needs to be sharpened?

Signs of a dull table saw blade can include burning marks on the wood, increased resistance while cutting, and rough or splintered edges.

To sharpen a table saw blade, one should first remove it from the saw and secure it in a vise.

Next, using a flat file or diamond stone at the correct angle, carefully file each tooth of the blade until its edge is restored.

Reinstalling the sharpened blade will result in cleaner and more accurate cuts.

Conclusion

In conclusion, selecting the right table saw blade is essential for achieving precise and efficient cuts. By understanding the basics of table saw blades, such as tooth count, material, and hook angle, beginners can make informed decisions when choosing a blade.

Whether it’s plywood projects, hardwood cutting, or intricate cuts, there are specific blades designed for each task. Just like a skilled surgeon selects the perfect instrument to perform delicate surgery with precision and care, choosing the right table saw blade is crucial for craftsmen to create masterpieces with accuracy and finesse.